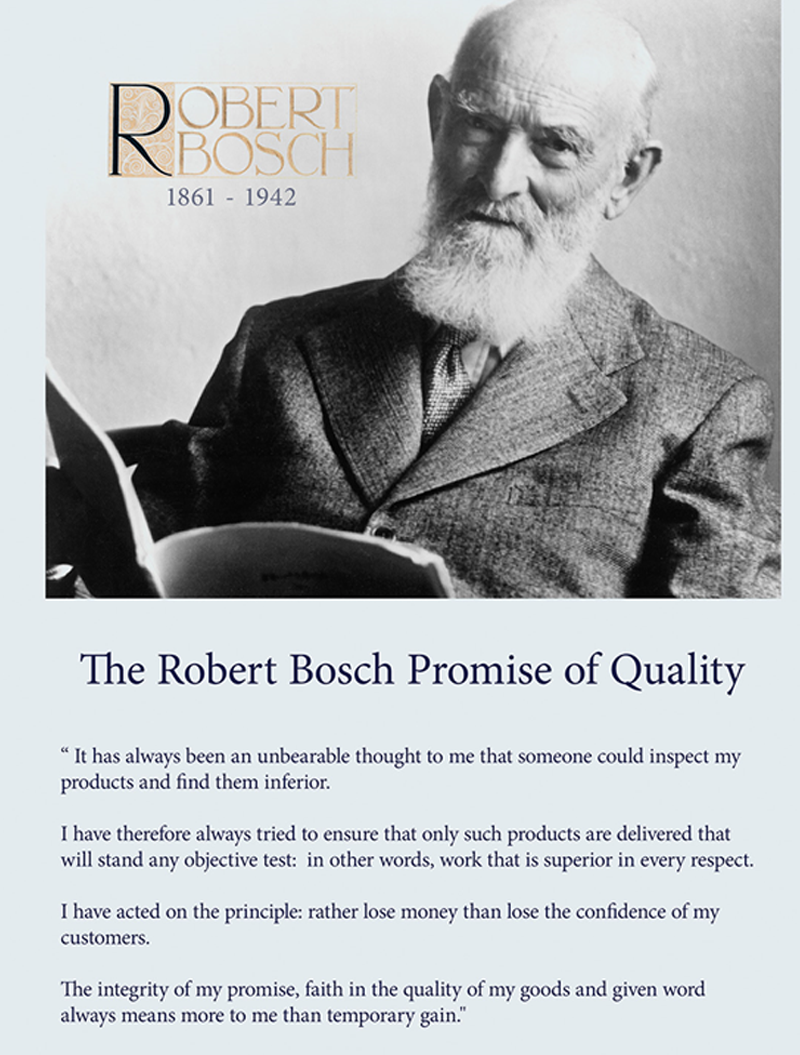

We follow BOSCH corporate culture which is governed by our customer centric approach.

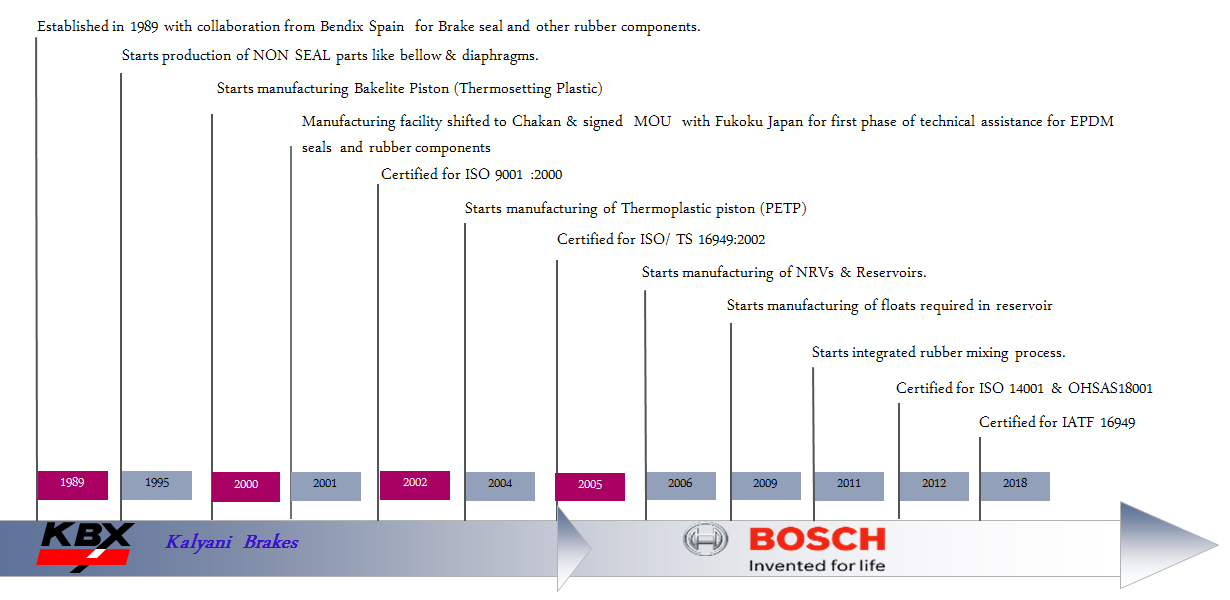

From the beginning in 1989, our passion for ingenuity has driven us to add critical new products using best in class manufacturing technologies.

Our focus had been in developing critical parts for brake application which give safety assurance to consumer. We have diversified customer base in Automobile industry from tier 1 to OEM's, where we also supply parts for power train and fuel injection systems.

Now we are adding new customers from other industry such as White goods, valves and agriculture industry.

We enable end to end solution to customer from design, compound, manufacturing and validation of products with the help of our in house experts & state of art engineering equipment.

Quality aim is for '0' defect supply, for which we maintain a strict adherence to Concepts such as 4M change, QA matrix, Safe Launch, Problem solving and Continuous improvement.

EHS aim is for '0' accidents, with key focus on fires hazard and employee safety. After achieving 36 months without accident we are further focused on saving of natural resources and reduction in carbon footprint.

We exist to provide safety critical rubber and plastic products and solutions that enhance the competitiveness of our customers. Our products help keep people safe.

To guarantee our continued success we will achieve a reasonable profit, continue to be the leader in our industry through individual and combined dedication, innovation and integrity. We will give our employees the opportunity for both personal and professional growth.

The future we want to create

To be the first choice for critical rubber and plastic products in the Bosch world

Future and result focus : Our actions are result-focused. This allows us to secure our future. It also creates a sound basis for the social initiatives of the company and the foundation.

Responsibility and sustainability : We act responsibly in the interest of our company, also taking the social and ecological impact of our actions into consideration.

Initiative and determination : We act on our own initiative, take entrepreneurial responsibility and pursue our goals with determination.

Openness and trust : We communicate important company matters in a timely and open fashion. This is the best foundation for a relationship built on trust.

Fairness : We deal fairly with our colleagues and business partners and view this fairness as a cornerstone of our corporate success.

Reliability, credibility, legality : We promise only what we can deliver, accept agreements as binding and respect and observe the law in all our business transactions.

Diversity : We appreciate and encourage diversity for the enrichment it brings and see it as essential for our success.

Chairman

Avinash Chintawar is a mechanical engineer from REC, Nagpur also has completed his Post graduate diploma in Management and a certified Cost accountant.

He had joined Bosch as management trainee in 1985 and worked in various departments such as process planning, manufacturing, projects & lean system.

He has lead various verticals and plants of Bosch at domestic and global level, presently he holds the position of Managing director at Bosch Chassis system India Pvt Ltd.

He was bestowed with the Young Engineer’s award and Engineering achievement award by Institute of Engineers India.

As Chairman of Precision seals he is giving strategic direction to make our footprint in various sectors, this will enable us to achieve a fourfold growth in next 2 years. His passion and vision of making Precision seals a world class supplier of critical rubber and plastic parts has filtered down to the whole team, motivating them for high achievements.

Plant Head

Ashok Patil is a mechanical engineer with a post graduation diploma in business management. Also he is an ICWA with an advanced management certification from IIM - Bangalore.

Starting his career as an engineer trainee in Bajaj auto from 1985 , he worked in production till 1989 gaining valuable experience as Front line trouble shooter.

He has been part of Bosch group since 1989 and worked in various areas as manufacturing, Quality, Lean systems and business excellence at domestic and global locations.

Ashok is a certified assessor of CII in business excellence, additionally he is a six sigma black belt and considered an authority in Lean manufacturing systems.

His leadership is guiding Precision seals into a new era of manufacturing excellence and customer delight, additionally it has been certified with IATF-16949 & also added its first OEM customer.